-

-

Industrial Robots

-

JR series (industrial six-axis)

-

JH Series (Welded/Hollow)

-

BR Series (Double Spin)

-

SR series (planar four-axis)

-

MD Series (Palletizing)

-

HC series (planar four-axis)

显示更多 -

-

Collaborative robot

显示更多 -

Compound robot

显示更多 -

Industrial Software

显示更多 -

Core Components

显示更多 -

Standard peripheral products

显示更多

-

-

-

Industry Program

-

3C industry

-

Shoes and clothing industry

-

Automotive industry

-

Home appliance industry

-

Metal Processing Industry

-

Other Industries

显示更多 -

-

Process Scheme

-

Welding application

-

Handling application

-

Assembly application

-

Machine application

-

Grinding application

-

Glue application

-

Spray Application

-

Other Applications

显示更多 -

-

Digital Solutions

显示更多

-

■System Overview

Digital twin is the precise mapping and dynamic simulation of physical world entities in digital space. Using advanced sensing technology, Internet of Things, big data analysis and high-performance simulation and other technical means, build a virtual model that runs synchronously with physical entities. Through real-time monitoring, data analysis and prediction, optimization decision-making and other processes, we can achieve in-depth insight and precise control of the physical world, so as to improve production efficiency, reduce operating costs, enhance product quality and accelerate product innovation.

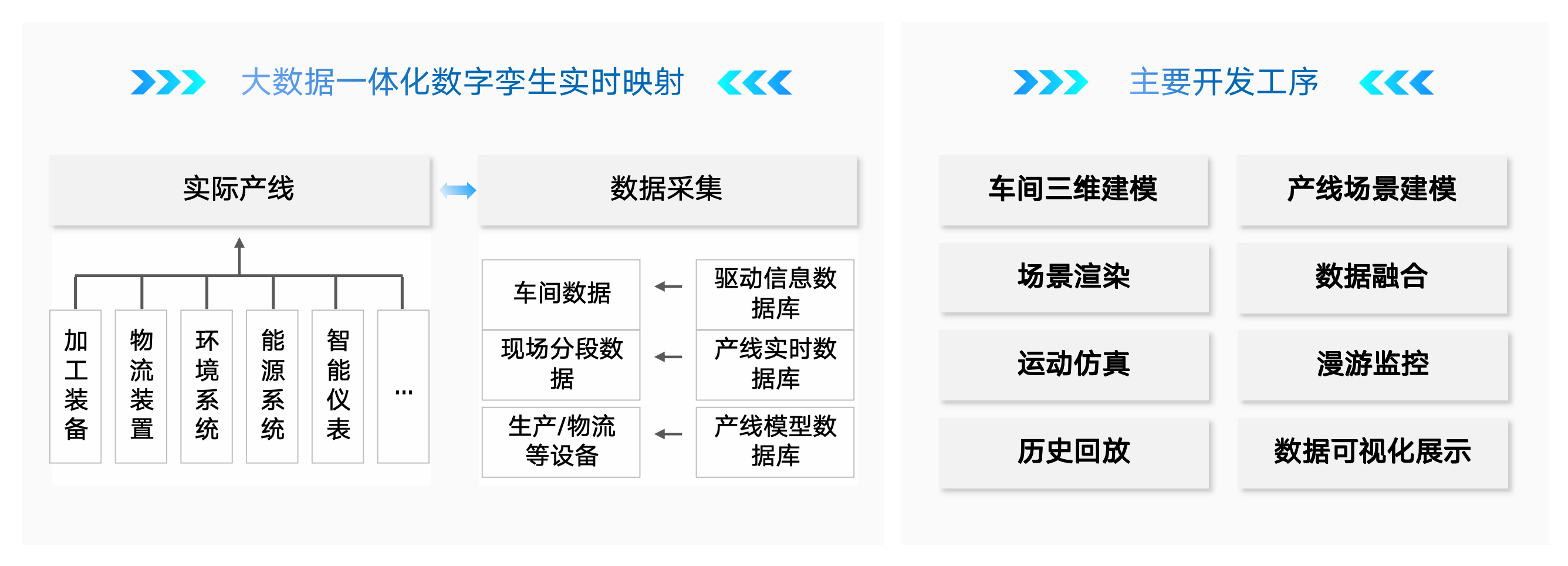

■overall system architecture

■%System technical route

For multi-source heterogeneous data such as processing equipment, logistics equipment, environmental systems, energy systems, intelligent instruments, sensors, etc. in the actual production line of dynamic physical workshop, a real-time perception model based on the new generation of information technology of the Internet of Things is established.

■System function

■System Case GIF

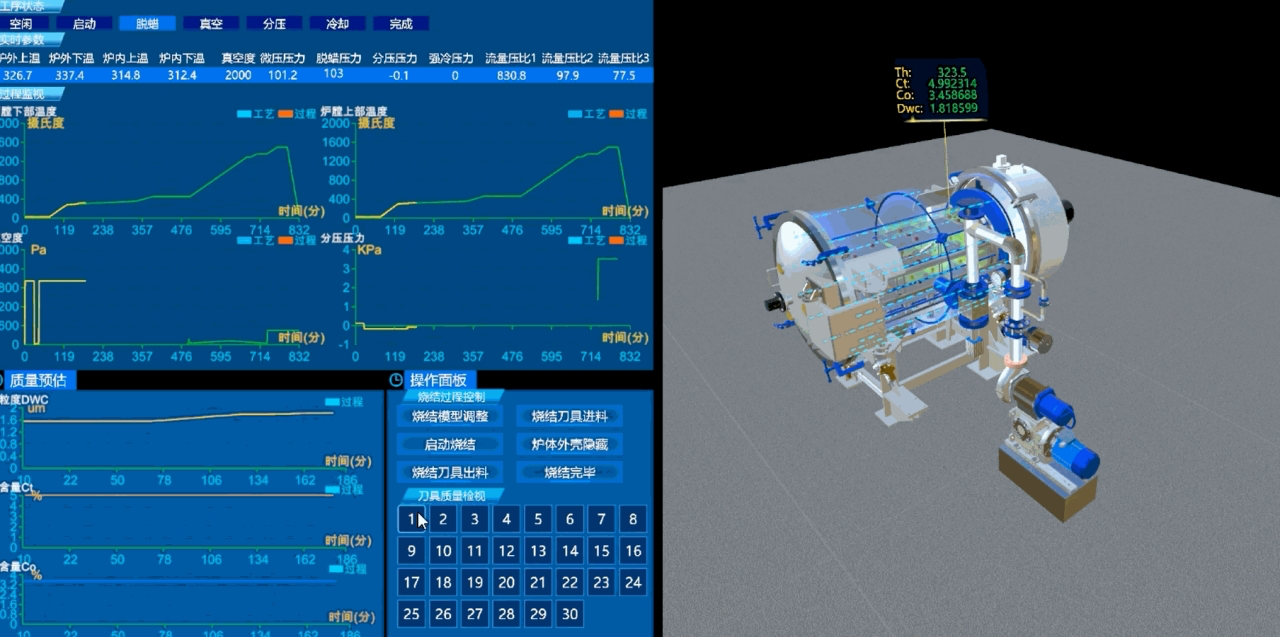

By obtaining the temperature, vacuum degree, micro-pressure pressure, partial pressure, strong cold pressure and other parameters of solid sintering furnace operation, the application of equipment state monitoring and motion process simulation, virtual sintering execution and historical data-driven sintering are realized. Based on the quality prediction model to predict the sintering quality of the current parameters, to assist managers in production decision-making and improve production efficiency.

■System Case GIF

The digital twin of the surface treatment production line realizes real-time monitoring, simulation, prediction and optimization of the whole process of surface treatment production through advanced technical means such as virtual simulation, big data analysis and cloud computing, so as to improve production efficiency, ensure production safety and promote the intelligent transformation of the surface treatment industry.

■System Case GIF

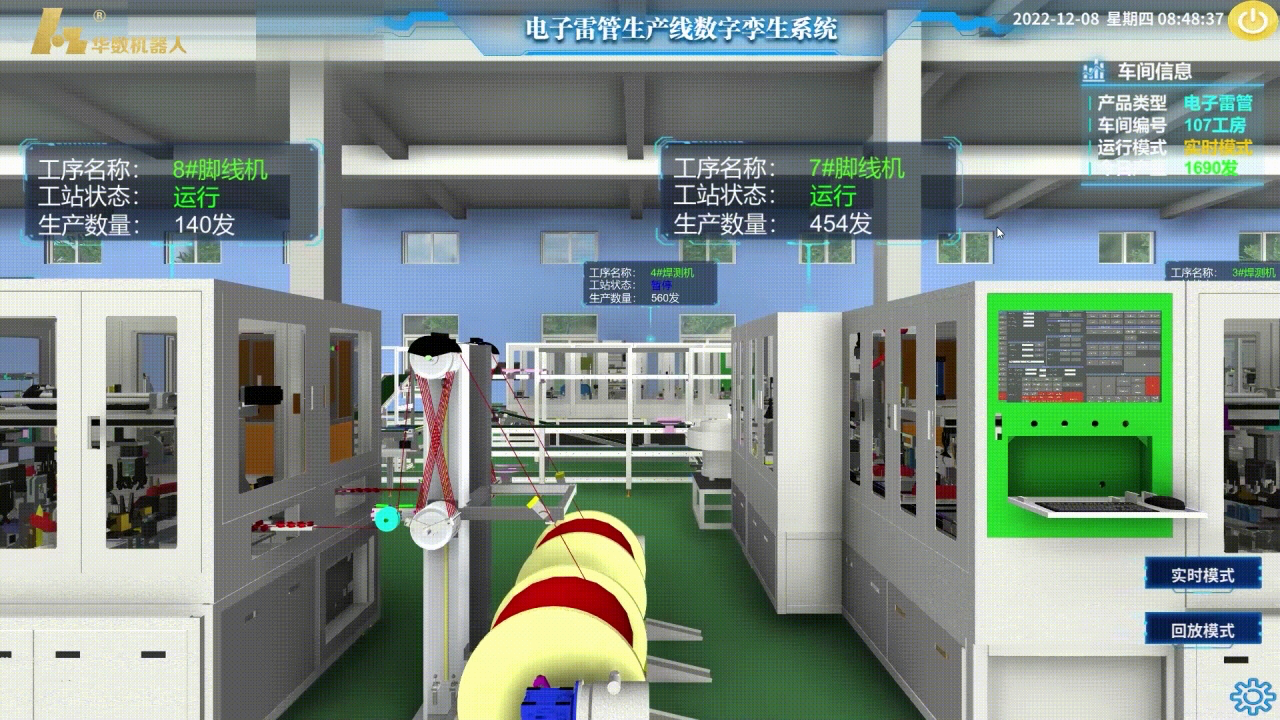

Digital twin of electronic detonator realizes real-time monitoring, simulation, prediction and optimization of the whole production process of electronic detonator through advanced technical means such as virtual simulation, big data analysis and cloud computing, so as to improve production efficiency, ensure production safety and promote the intelligent transformation of civil explosive industry.

■System Case GIF

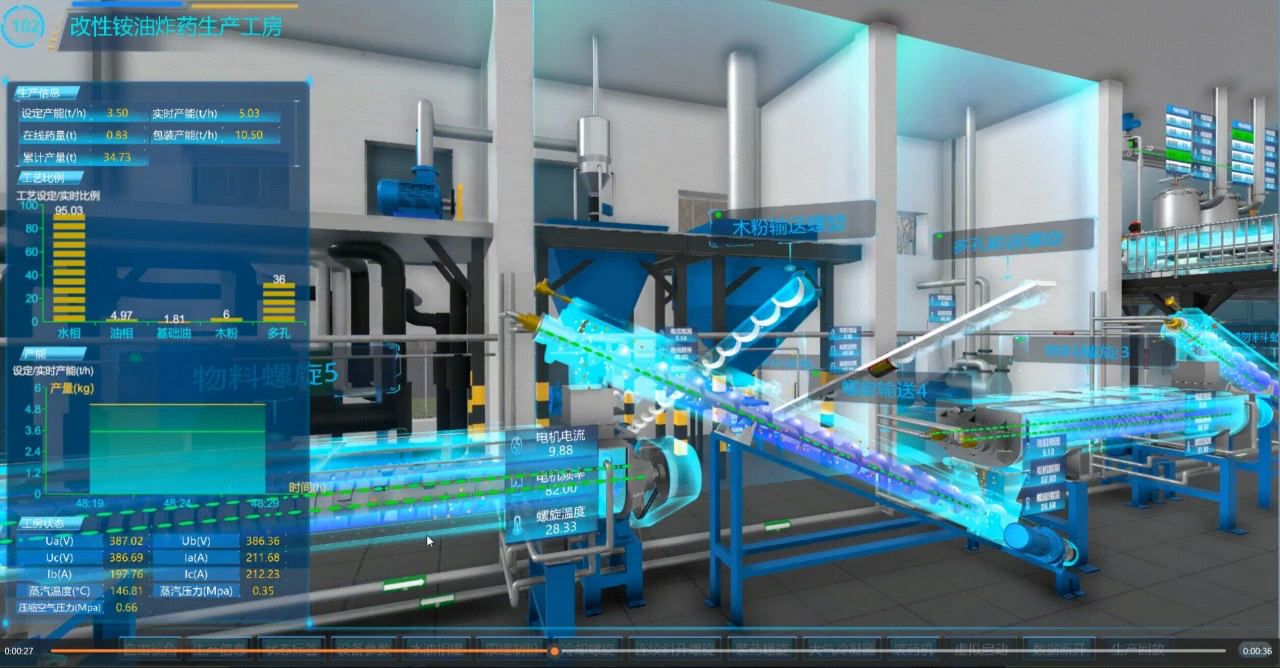

The digital twin of industrial explosives realizes real-time monitoring, simulation, prediction and optimization of the whole process of industrial explosive production through advanced technical means such as virtual simulation, big data analysis and cloud computing, so as to improve production efficiency, ensure production safety and promote the intelligent transformation of the explosive manufacturing industry.

Provide professional robot products and services,

Make manufacturing easier, make life better.

Service Hotline

If you have any questions or want to know more information, welcome to leave a message!

Leave us a messageCOOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.