-

-

Industrial Robots

-

JR series (industrial six-axis)

-

JH Series (Welded/Hollow)

-

BR Series (Double Spin)

-

SR series (planar four-axis)

-

MD Series (Palletizing)

-

HC series (planar four-axis)

显示更多 -

-

Collaborative robot

显示更多 -

Compound robot

显示更多 -

Industrial Software

显示更多 -

Core Components

显示更多 -

Standard peripheral products

显示更多

-

-

-

Industry Program

-

3C industry

-

Shoes and clothing industry

-

Automotive industry

-

Home appliance industry

-

Metal Processing Industry

-

Other Industries

显示更多 -

-

Process Scheme

-

Welding application

-

Handling application

-

Assembly application

-

Machine application

-

Grinding application

-

Glue application

-

Spray Application

-

Other Applications

显示更多 -

-

Digital Solutions

显示更多

-

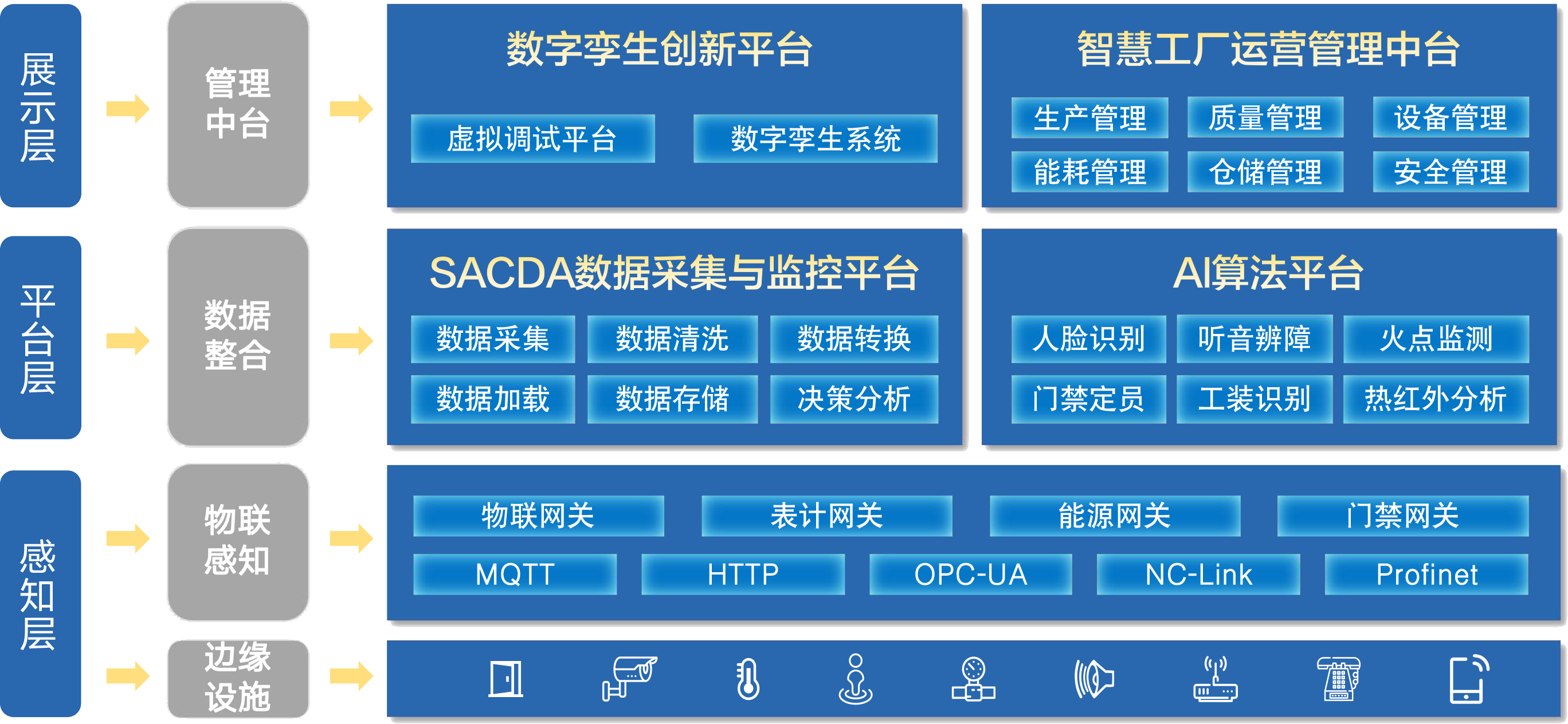

MOM manufacturing operations management system is a set of digital, networked, intelligent in one of the enterprise production management tools. It integrates the internal and external resources of the enterprise, realizes the comprehensive optimization and fine management of the production process, improves the production efficiency and quality through real-time monitoring, data analysis and mining, and helps the enterprise to achieve sustainable development and competitive advantage.

■%MOM system overall solution architecture production management system

■%production management system

■%equipment management system

The equipment management system is composed of mobile phones in the management background. It is fast on hand and short on delivery. It is a real "small budget and big improvement". It provides enterprises with the best business practices of equipment management. It helps all managers to cooperate in all aspects of equipment management and share information.

■%Quality Management System

Traceability is an important feature of MES system, traceability data model can not only record the production process data, but also can be extended to quality traceability, procurement traceability and other aspects, which is of great significance to the enterprise manufacturing process control and manufacturing process improvement.

■%Energy Management System

Energy consumption monitoring: real-time monitoring of the overall energy consumption situation and energy consumption trend of the enterprise, and classification according to different energy categories such as electricity, water, gas, coal, oil, etc., real-time monitoring and abnormal alarm of energy-using buildings and energy-using equipment, and providing abnormal recording function.

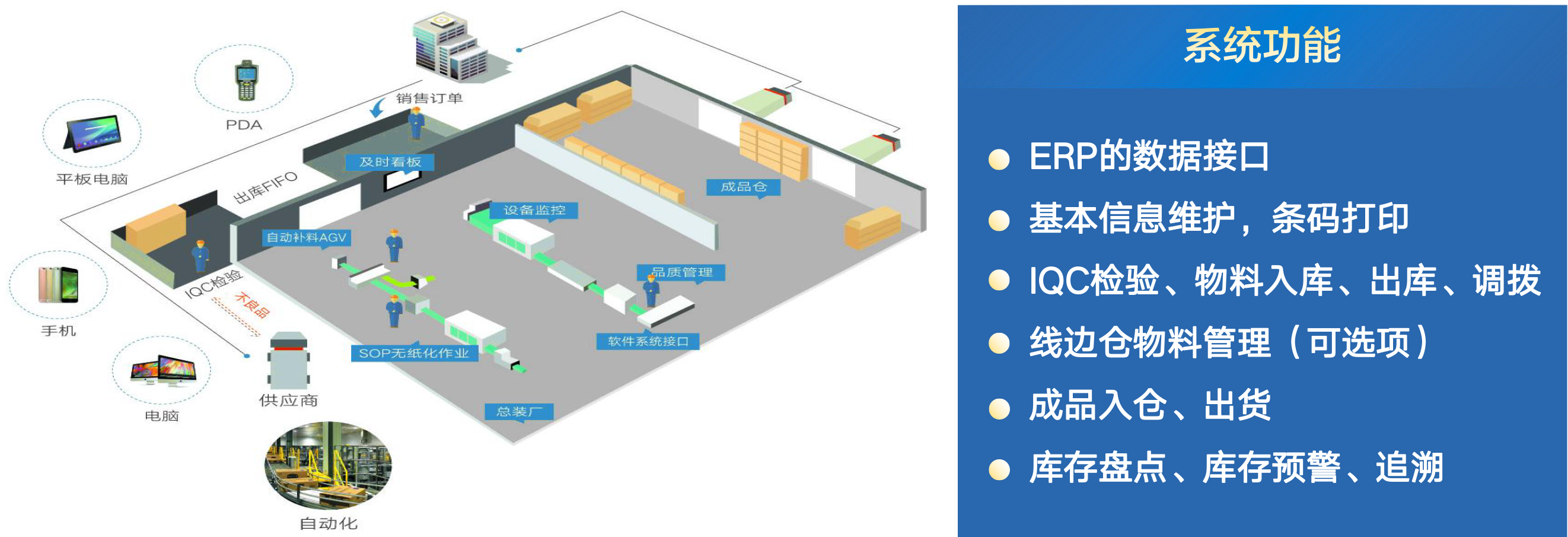

■%Warehouse Management System

Intelligent warehouse management system (Warehouse Management System) includes receipt business, issue business, warehouse transfer and inventory transfer. According to the production schedule of MES system, the system automatically calculates the demand for the first set of materials for production line opening, pushes it to the warehouse keeper's handheld terminal and material preparation kanban, and guides the preparation and distribution of the first set of materials. After normal production, the system obtains the emergency demand status of materials according to the returned logical data such as machine equipment capacity, actual deduction number, scrap number and production priority, and notifies or pushes material preparation instructions through kanban, email and SMS.

■%safety management system

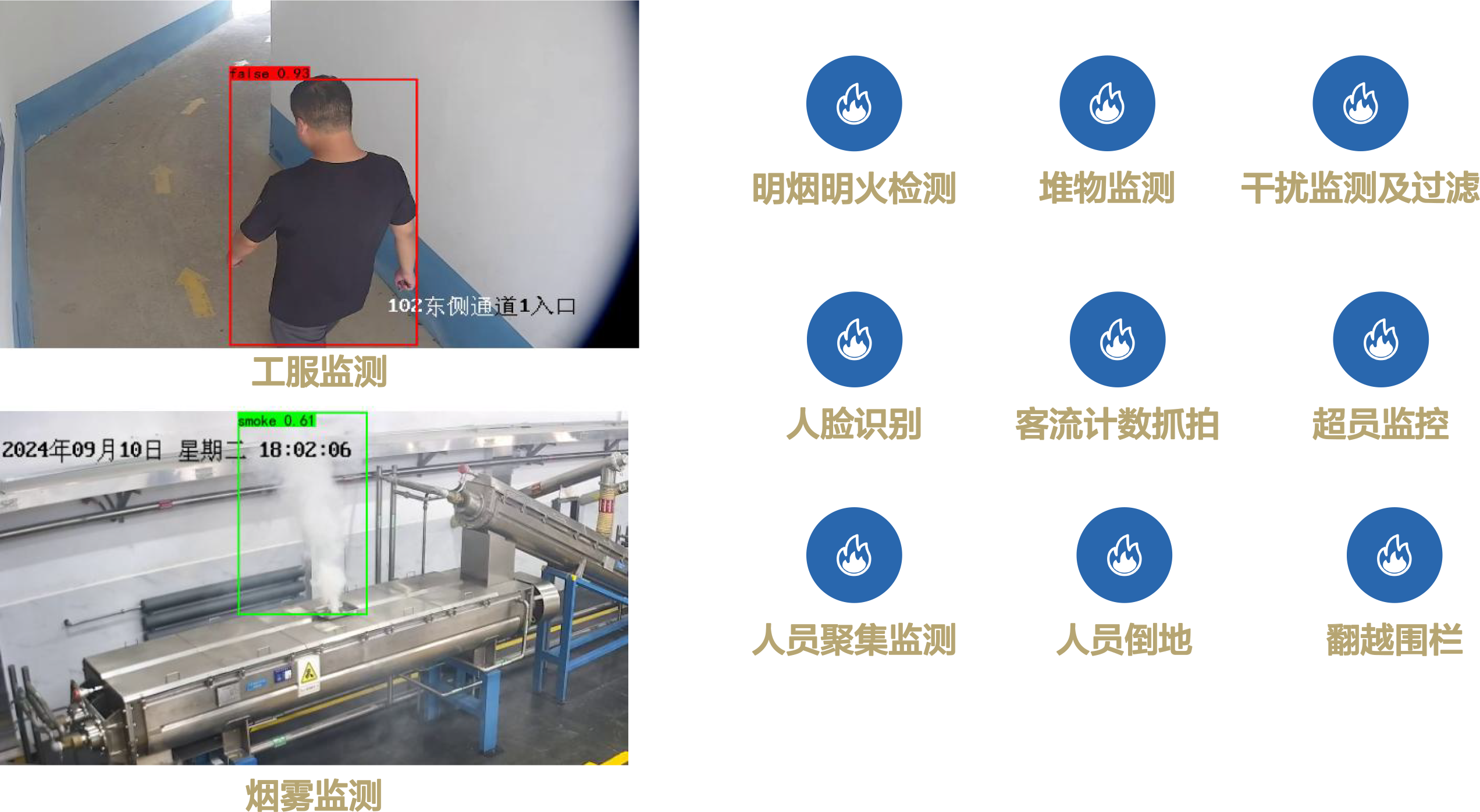

■%Artificial Intelligence AI-Target Detection Algorithm

Provide professional robot products and services,

Make manufacturing easier, make life better.

Service Hotline

If you have any questions or want to know more information, welcome to leave a message!

Leave us a messageCOOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.