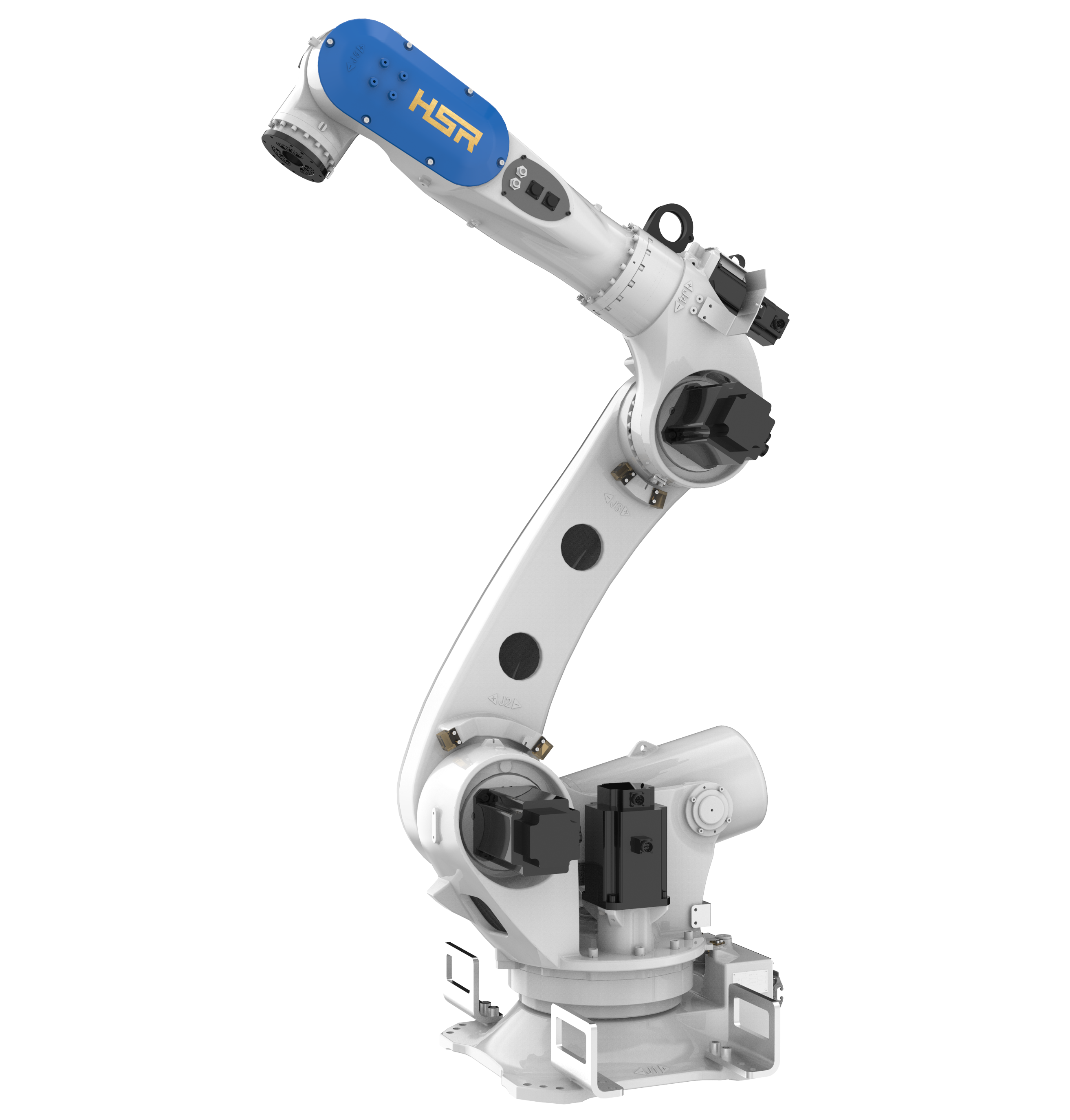

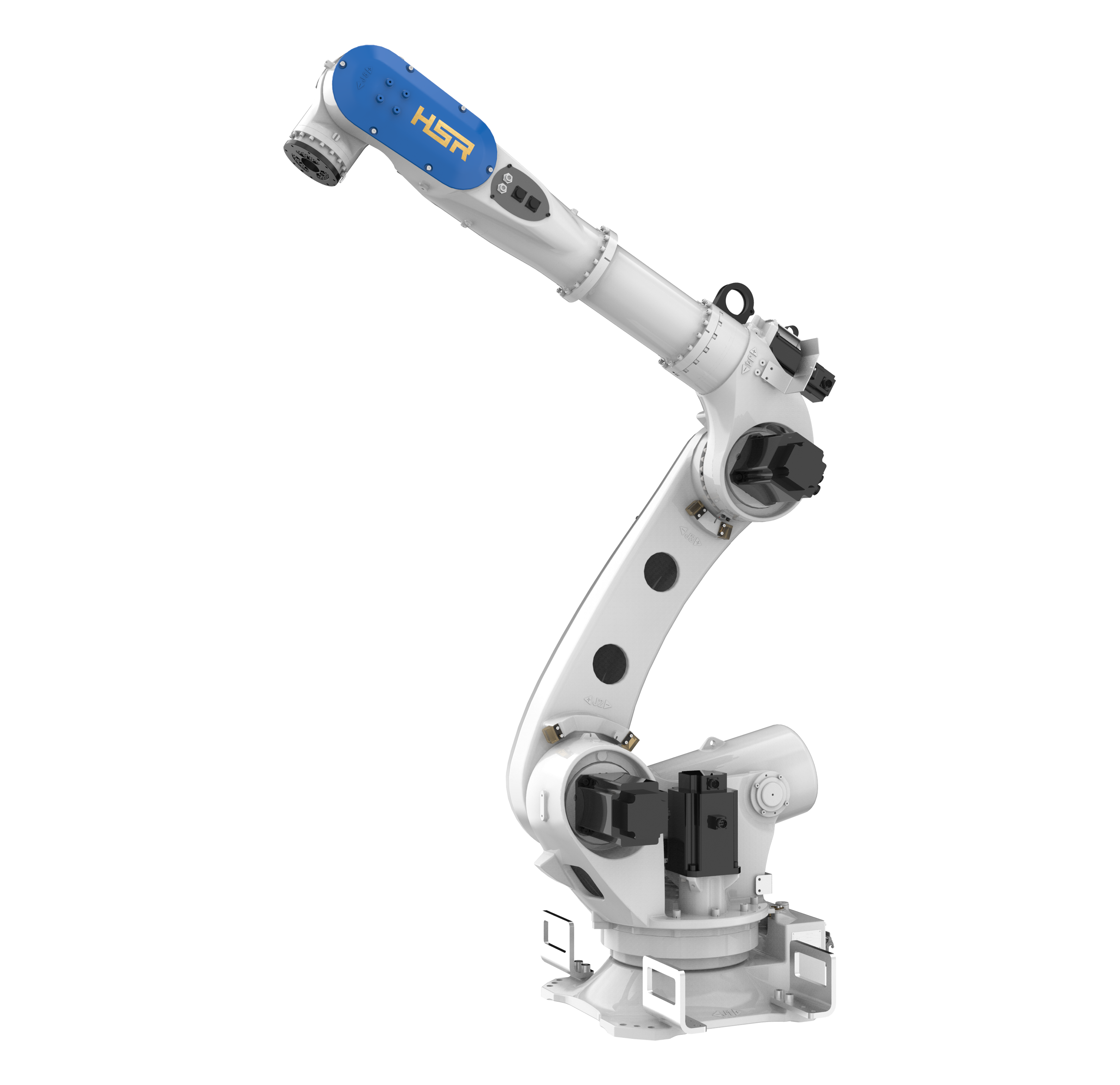

JR series (industrial six-axis)

As a traditional vertical multi-joint robot, Huashu JR series robot has a load of 3kg-500kg and an arm span of 500mm-3100mm. It provides more than 20 types of robot products and has the characteristics of high precision, high rigidity, high stability and strong versatility.

01

High precision

JR series robots adopt advanced control systems, precise mechanical transmission, optimized structural design, advanced calibration algorithms and other technologies, so that JR series robots can show high precision in various application scenarios, and the repeated positioning accuracy is within ± 0.05mm.

02

high rigidity

JR series robot transmission mostly adopts high-rigidity RV and gear transmission. Through lightweight design of mechanical structure and topology optimization simulation, a lightweight and high-rigidity robot arm is created, which not only reduces the mass of the robot body, but also improves its load capacity and rigidity.

03

High stability

The JR series robot adopts the adaptive control algorithm of the advanced dynamic model, which can automatically adjust its motion parameters according to the working environment and task requirements, thereby improving its stability and adaptability. The average failure-free time MTBF of multiple models reaches 8W hours.

04

Strong versatility

JR series robots have six rotation axes, which can realize complex three-dimensional space movement and flexibly adjust posture and angle. By adapting different end effectors and corresponding application process packages, JR series robots can flexibly adapt to various complex and fine work tasks, such as surface treatment, measurement, welding, palletizing, assembly, loading and unloading and other applications.

Huashu JR series robots provide application process packages for different industries such as 3C, kitchen and bathroom, lithium battery, automobile, metal processing, etc. With offline programming technology and digital technology, JR series robots show the characteristics of wide application, good stability and strong professionalism.

3C industry

High precision assembly:With its micron-level positioning accuracy, the JR series is very suitable for the precise assembly of small and medium-sized components in 3C products, such as the assembly of small parts such as mobile phones and tablets. The representative models are JR603,JR607,JR612 and JR630.

Quick line change to adapt to flexible production:Faced with the characteristics of fast iteration of 3C products, JR robots support rapid adjustment and programming, adapt to diversified production needs, and reduce line change time. The representative models are JR612 and JR607.

Visual guidance and detection:The integrated vision system enables product quality inspection and precise positioning of parts to improve production quality and efficiency. The representative models are JR603,JR607 and JR612.

high quality grinding:Through the combination of offline programming, polishing process package and force control polishing technology, the robot can monitor and feedback polishing data in real time to ensure polishing quality and consistency, greatly improving the yield and quality consistency of polishing products. The representative models are JR612 and JR630.

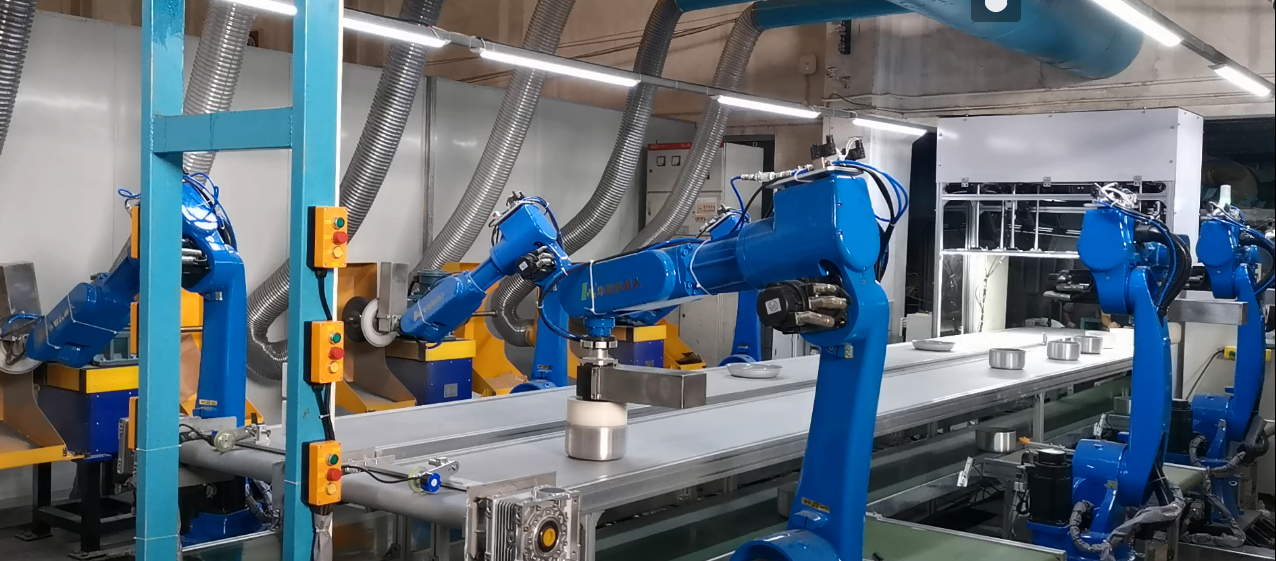

Kitchen and bathroom industry

Corrosion resistant material and sealing treatment:Considering the particularity of the manufacturing environment of kitchen and bathroom products, JR series robots use corrosion-resistant materials and carry out special sealing treatment to extend the service life of the equipment. The representative models are JR612,JR630 and JR680.

Surface treatment process:In the surface treatment links such as polishing, polishing and spraying, JR robot moves delicately. The combination of offline programming, polishing process package and force control polishing technology ensures the uniform appearance and texture of the product and improves the product grade. The representative models are JR612 and JR630.

automated pipeline integration:It is easy to integrate with the kitchen and bathroom product production line to realize the fully automated process from raw material processing to finished product packaging. The representative models are JR612 and JR630.

Lithium battery industry

Pole ear welding and top cover welding in battery cell manufacturing:JR series robots are equipped with welding equipment to accurately weld the tabs and top cover of the battery core to ensure welding quality and stability. The representative models are JR680 and JR6210.

Module assembly module stacking:JR series robots are used for module stacking, and realize precise stacking and positioning of modules through precise control system and sensor technology. The representative models are JR6210 and JR6360.

PACK line module assembly:In the PACK module assembly line, JR series robots are used for module assembly, including module handling, positioning and installation. Detection and testing: JR series robots are used for the detection and testing of battery packs. By carrying corresponding detection equipment and sensors, the performance and quality of battery packs are monitored and evaluated in real time. The representative models are JR6210 and JR6360.

Back-end handling and packing handling and palletizing:JR series robots are used for handling work at the back end of the lithium battery production line. The finished battery is automatically removed from the production line and transported to a designated position. It can also realize fast packing and palletizing of battery packs and improve production efficiency. The representative models are JR6360 and JR6500.

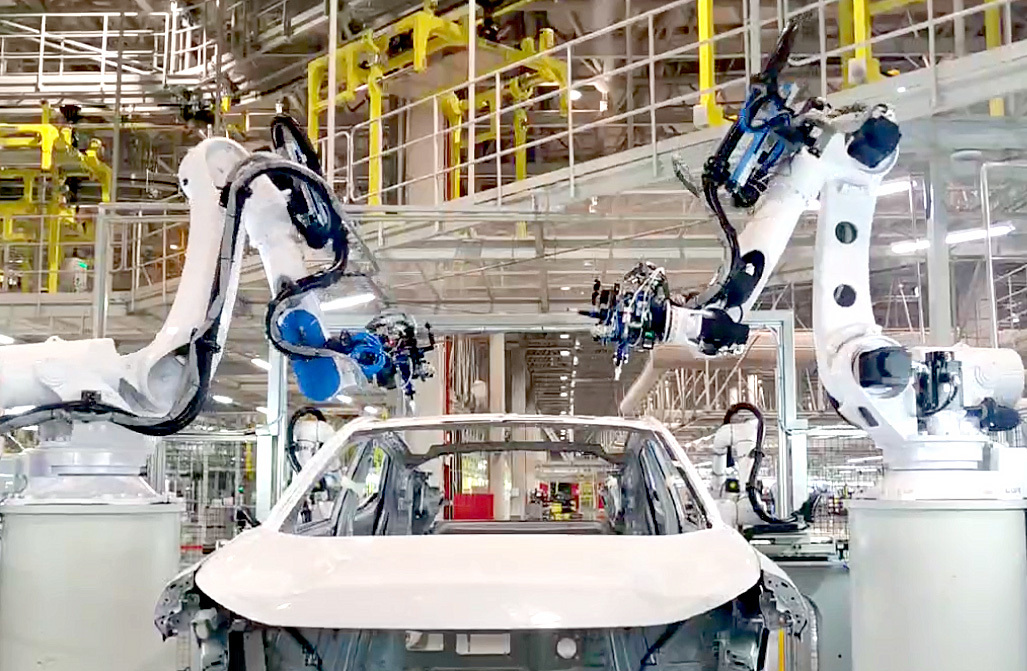

Automotive industry

High strength and long-lasting working ability:JR series robots have high-strength mechanical structure and are suitable for high-strength operations in automobile manufacturing, such as welding and handling heavy components. Representative models are JR6210,JR6300,JR6360.

Complex path welding: In the application of automobile body welding, with high precision and multi-degree of freedom, high-quality welding of complex three-dimensional surfaces is realized. The representative models are JR6210,JR6210L.

three-dimensional car parts gluing:For complex-shaped auto parts, such as engine compartment covers, doors, windshields, canopies, etc., JR series robots are equipped with glue supply systems and glue coating processes to perform glue coating operations flexibly and with high precision to meet various glue coating requirements. The representative models are JR6210,JR6210L.

automated flexible production line:Support the construction of highly flexible automated production lines, quickly adapt to model changes, improve production flexibility and market response speed. The representative models are JR6210 and JR6360.